Product Introduction

STC series punch press machine are produce by Qiaosen machine factory, which built to meet or exceed JIS Class 1 accuracy standards. Qiaosen punching machine adopt forced Lubrication system with default monitor ensures the operation reliability.User-friendly design and all-function electric control system provide high automation compatibility.

Gap press frame made of high strength steel frames and Quenching & Grinding Process for Slide-Guide,which can make the press machine have minimizing deflection and high accuracy and provide increased tool life.

The material of presses crankshaft are forged 42CrMo alloy,precision-machined gears and other drive train components are designed for smooth power transmission, quiet operation and long life. STC series double crank press machine are dry clutch system,which has longer service life of the clutch system ,high single stroke rate and high torque outputs performance.

Siemens based control platform and user-friendly touch screen operation interface are standardized in all QIAOSEN’s precision press machine, make the puching machine provides ease of operation and expandable capabilities. Easy to integration with other automation system(Such as press transfer and robots). Other brands of control can be furnished upon request.

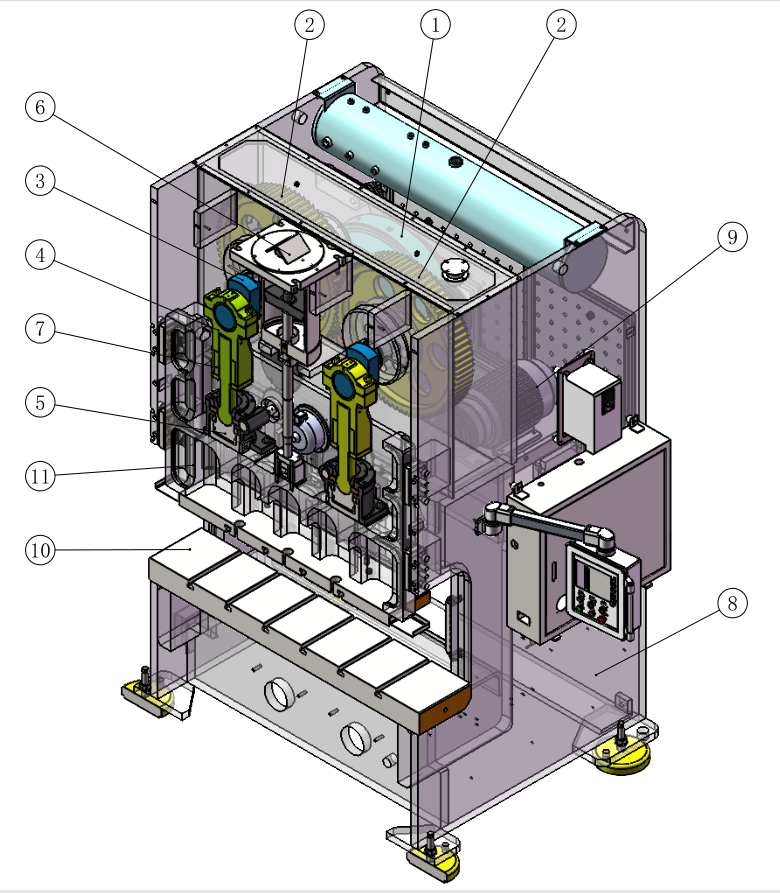

Product Details

① Flywheel, Dry Clutch Brake, Gear Shaft (Transmission System)

② Main gear

③ Crankshaft

④ Connecting Rods

⑤ Hydraulic Overload Protection

⑥ Balancer

⑦ Adjusting nut

⑧ Frame

⑨ Main Motor

⑩ Bolster

⑪ Slide Frame

Specifications

Technical parameter

| Specifications | Unit | STC-110 | STC-160 | STC-200 | STC-250 | STC-315 | |||||

| Mode | V-type | H-type | V-type | H-type | V-type | H-type | V-type | H-type | V-type | H-type | |

| Press capacity | Ton | 110 | 160 | 200 | 250 | 315 | |||||

| Rated tonnage point | mm | 5 | 3 | 6 | 3 | 6 | 3 | 7 | 3.5 | 7 | 3.5 |

| Slide strokes per minute | S.P.M | 35~65 | 50~100 | 30~55 | 40~85 | 25~45 | 35~70 | 20~35 | 30~60 | 20~40 | 40~50 |

| Slide stroke length | mm | 180 | 110 | 200 | 130 | 250 | 150 | 280 | 170 | 280 | 170 |

| Max die height | mm | 400 | 435 | 450 | 485 | 500 | 550 | 550 | 605 | 550 | 605 |

| Slide adjustment amount | mm | 100 | 100 | 120 | 120 | 120 | |||||

| Slide Area | mm | 1400*500 | 1600*550 | 1850*650 | 2100*700 | 2200*700 | |||||

| Slide Thickness | mm | 70 | 70 | 95 | 95 | 95 | |||||

| Bolster Area | mm | 1800*650 | 2000*760 | 2400*840 | 2700*900 | 2800*900 | |||||

| Bolster Thickness | mm | 130 | 150 | 170 | 170 | 190 | |||||

| Platform to floor distance | mm | 830 | 990 | 1070 | 1100 | 1100 | |||||

| Die cushion capacity | Ton | 3.6*2set | 6.3*2set | 10*2set | 14*2set | 14*2set | |||||

| Main motor power | KW*P | 11*4 | 15*4 | 18.5*4 | 22*4 | 30*4 | |||||

| Air pressure | kg*cm² | 6 | 6 | 6 | 6 | 6 | |||||

| Press accuracy grade | Grade | JIS 1 | JIS 1 | JIS 1 | JIS 1 | JIS 1 | |||||

| Press dimension(L*W*H) | mm | 1745*2000*3059 | 1940*2200*3709 | 2235*2620*3849 | 2545*3000*4304 | 2545*3100*4304 | |||||

| Press weight | Tons | 14.2 | 22 | 30.5 | 40.5 | 48 | |||||

| Die cushion active area | mm² | 350*235*2set | 410*260*2set | 540*350*2set | 640*470*2set | 690*470*2set | |||||

| Our company is ready to carry out research and improvement work at any time. Therefore, the size design characteristics specified in this catalogue can be changed without further notice. | |||||||||||

● Heavy one-piece steel frame, minimizing deflection, high accuracy.

● OMPI pneumatic dry clutch brake,longer service life.

● 6 points slide guiding, Adopt Quenching & Grinding Process for Slide-Guide,which can make the press machine higher accuracy & low wear and provide increased tool life.

● Forged 42CrMo alloy material crankshaft, its strength is 1.3 times higher than that of #45 steel, and service life is longer.

● Copper sleeve is made of tin phosphorus bronze ZQSn10-1, which has a strength 1.5 times higher than that of ordinary BC6 brass.

● Highly sensitive hydraulic overload protection device,effectively protect the service life of the presses and tools.

● Built to JIS Class I accuracy standard.

● Optional Die Cushion.

Standard Confirguration

| > | QS operating system | > | Second degree falling protecting device |

| > | Hydraulic overload protection device | > | Air blowing device |

| > | Electronic cam device | > | Mechanical shockproof feet |

| > | Electric slider adjusting device | > | Mis-feeding detection device reserved interface |

| > | Variable frequency variable speed motor (adjustable speed) | > | Maintenance tools and toolbox |

| > | Air blowing device | > | Main motor reversing device |

| > | Digital die height indicator | > | Light Curtain (Safety Guarding) |

| > | Slider and stamping tools balance device | > | Power outlet |

| > | Rotating cam controller | > | Electric grease lubrication device |

| > | Crankshaft angle indicator | > | Touch screen (pre-break, pre-load) |

| > | Electromagnetic counter | > | Fixed two-handed operating console |

| > | Air source connector | > | LED die lighting |

Optional Configuration

| > | Customization Per Customer Requirement | > | T-type movable two handed console |

| > | Die Cushion | > | Re-Circulating Oil lubrication |

| > | Foot switch | > | Wet clutch |

| > | Quick Die Change System | > | Anti-Vibration Isolator |

| > | Slide knock out device | > | Tonnage Monitor |

| > | Turnkey System with Coil Feedline and Automation System |